2024 Wool Pellet Study

As the 2024 season comes to a close, we are busy compiling our data into a user-friendly format that will be accessible to the public.

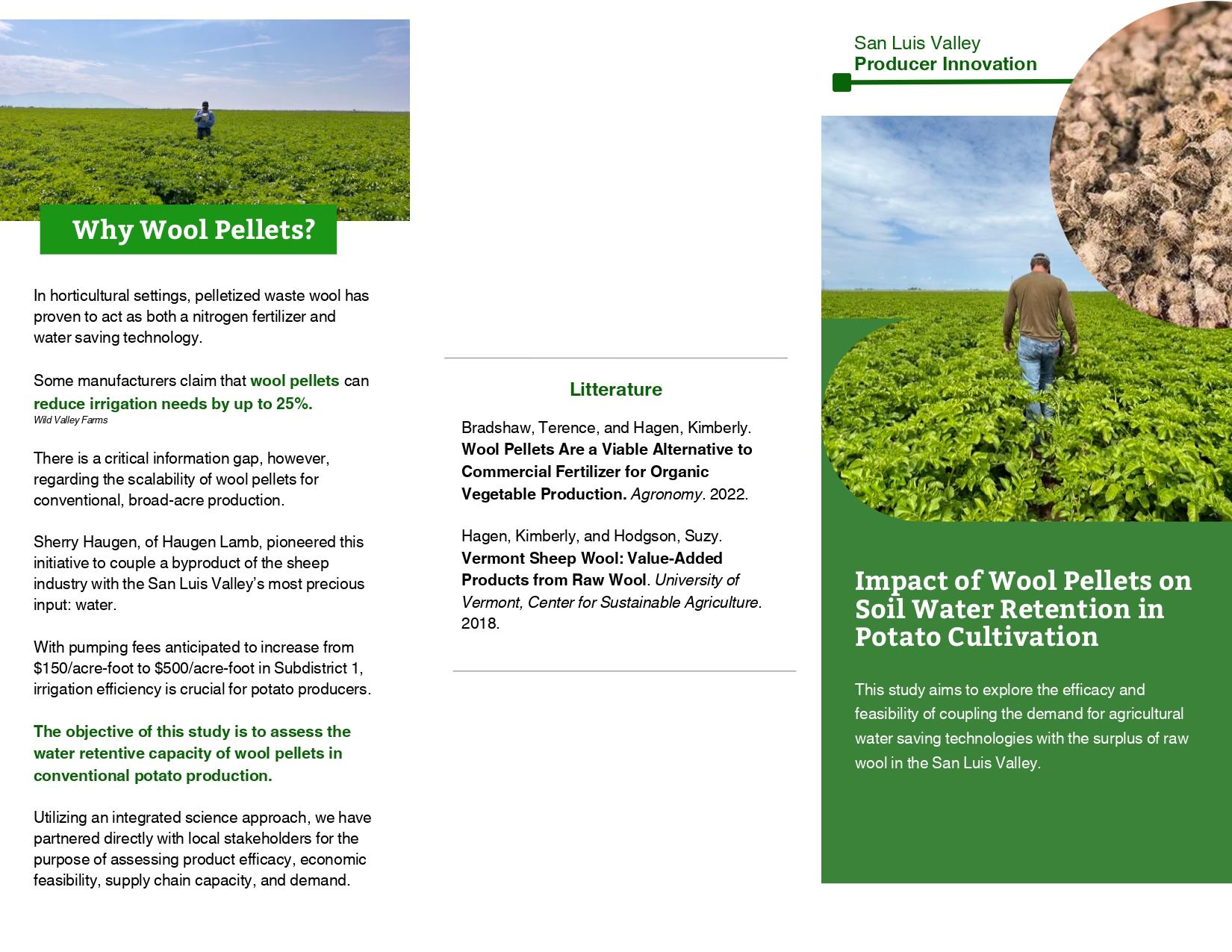

At the beginning of the season, the San Luis Valley Wool Pellet Project (SLVWPP) had to change its location from the CSU Research Farm to a local potato producer's field in Hooper, CO. Due to this last-minute switch and unforeseen challenges (inability to test variable rate irrigation, soil variations, difficulties spreading the pellets in a standard fertilizer spreader, technological errors with soil moisture monitoring equipment, etc.), the data collected from the 2024 study is currently inconclusive. We look forward to further wool pellet efficacy testing in 2025!

2024 Study Brochure

Looking Forward to 2025

Despite the challenges faced during the 2024 study, we are excited at the promise of continuing the study in 2025!

The 2025 study will take place at the CSU Research Farm, where the ability to closely monitor variables will be achievable. The following variables will be tested as wool pellets are applied to potatoes and possibly cover crops: application rates, irrigation rates, and soil moisture levels. We will also continue to determine the economic scale and market data pertaining to wool pellets.

The SLVWPP is also currently seeking funding to purchase prototyped wool pellet-producing equipment to generate a product that is suitable for agricultural operations. The research to create an effective pellet was inspired by the challenge faced during the 2024 study of applying the pellets through a fertilizer spreader. The pellets we received for the project were not suitable for a standard spreader as they were not compacted enough to prevent expansion and oil expression; however, with assistance from Colorado Mill Equipment and RapidGranulators, we have found that a satisfactory product can be produced using the right equipment. This will be a pivotal component of our 2025 study!